Flexible Metal Hoses and Assemblies

Advanced Flexible Metal Hose Solutions

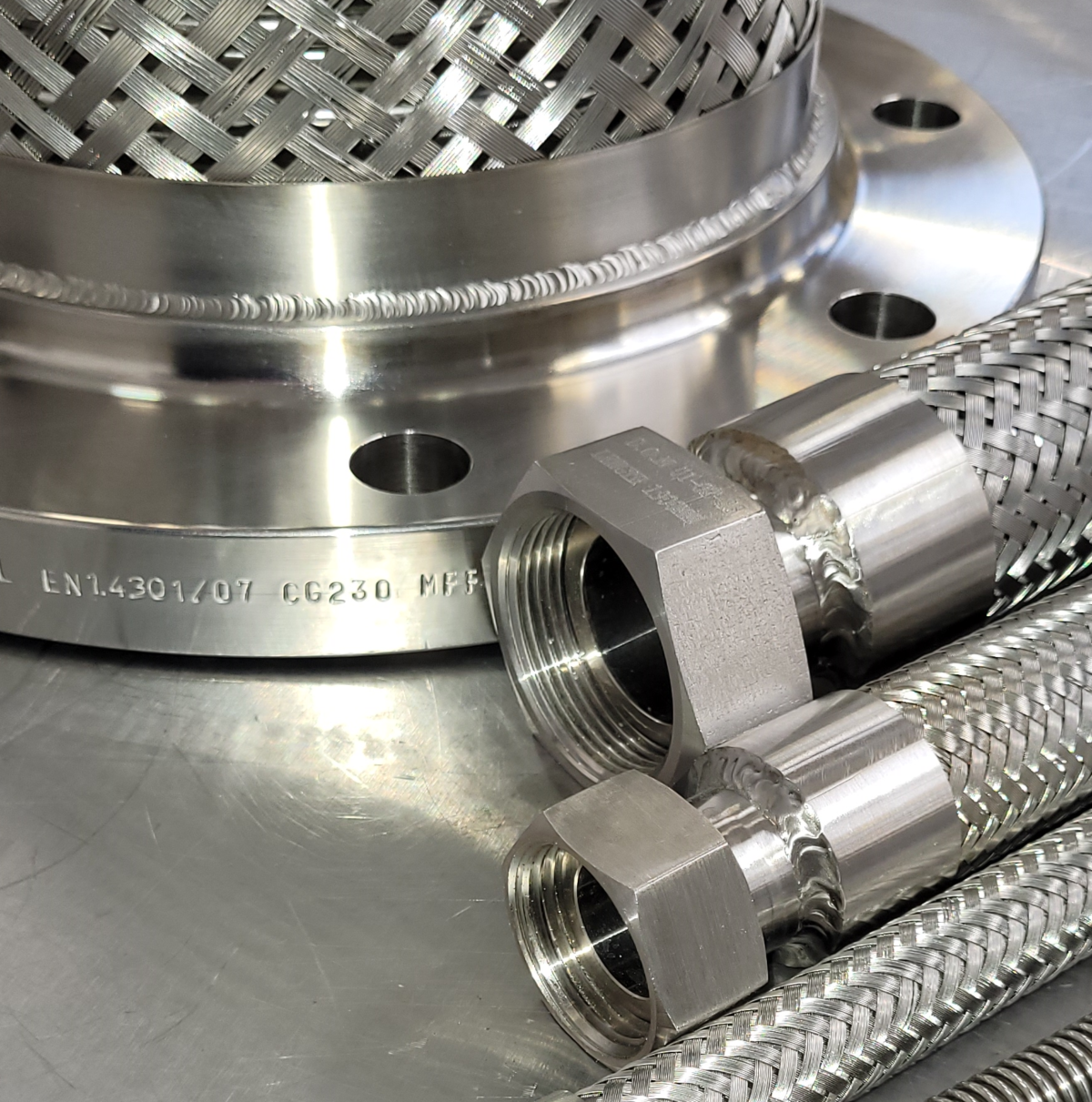

At Flexmetallic, we specialise in the design and manufacture of flexible metal hoses and hose assemblies engineered to perform under the most demanding industrial conditions. Our products are designed for use in systems where pressure, temperature, and vibration require robust, leak-free, and mechanically resilient solutions.

Flexible metal hoses are specifically designed to accommodate movement, absorb vibration, and compensate for thermal expansion or misalignment within a pipework system. Constructed from high-grade stainless steel and specialist alloys, they provide outstanding durability, flexibility, and resistance to corrosion, pressure, and temperature extremes.

Our range of flexible metal hoses and assemblies is used extensively across sectors including power generation, chemical and petrochemical processing, HVAC, water treatment, and cryogenic transfer. Every product is designed to meet the technical and performance standards demanded by these critical industries.

Core Solutions

Reliable Transfer & Robust Design

Our flexible metal hoses and assemblies ensure safe transfer of liquids and gases, with corrugated stainless-steel construction for top flexibility and structural strength under dynamic conditions.

Braided Options for Extra Strength

Single or double external stainless-steel braid boosts pressure resistance, controls elongation, and safeguards against abrasion and impact, tailored for demanding specifications.

Custom Engineered Assemblies

Assemblies are manufactured to precise bore, length, pressure, temperature, and fitting needs. End options include flanged, threaded, or welded types. Protective covers and casings available.

Versatile Industry Applications

Trusted across steam systems, HVAC, chemical/petrochemical, cryogenics, water treatment, and manufacturing. Suitable wherever movement, pulse, or vibration protection is essential.

High-Performance Construction & Materials

Produced from premium stainless steel grades (304, 316, 321) and specialty alloys for durability, corrosion resistance, and strength. Multi-layer builds and custom braiding for extreme demands.

Certified Performance & Compliance

Each hose and assembly is rigorously pressure tested, certified, and traceable to meet regulated industry standards and safety requirements.

Comprehensive Fittings & Accessories

Wide choice of end fittings in customizable materials for process compatibility. Accessories include protective covers, interlock casings, and fire sleeves for enhanced service life.

Expert Installation & Support

Guidance on bend radius, alignment, anchoring and maintenance. Regular inspection is advised for wear and vibration fatigue. Technical support assists at every stage—specification, installation, troubleshooting.

Selection Guidance

Specialist engineers advise on choosing the right hose or assembly by pressure, temperature, medium, movement, and installation environment, ensuring safety and optimal system performance.

Construction and Materials

Flexmetallic hoses are typically manufactured from stainless steel grades such as 304, 316, and 321, chosen for their balance of corrosion resistance, strength, and flexibility. The corrugated hose section provides the required flexibility, while the external stainless-steel braid adds mechanical strength and pressure capability.

For more demanding duties, alternative materials and multi-layer constructions can be specified to enhance chemical resistance, temperature range, or fatigue life. The braiding process uses precision-woven stainless-steel wire that allows the hose to flex freely while maintaining control over expansion and vibration.

This engineered construction ensures long-term reliability in both static and dynamic service conditions, making it suitable for high-pressure, high-temperature, or high-vibration environments.

Industry Applications

Flexmetallic flexible metal hoses and assemblies are used across a broad range of industrial sectors and service conditions, including:

- Steam and condensate lines

- Chemical and petrochemical transfer

- Cryogenic and liquefied gas handling

- Water and fluid transfer systems

- HVAC and building services

- Process engineering and manufacturing operations

Each application benefits from the hose’s ability to accommodate movement, absorb vibration, and maintain system integrity under fluctuating temperature and pressure.

Performance, Certification and Compliance

Every Flexmetallic hose and assembly is manufactured and tested in accordance with relevant industry standards. Hoses are rated for specific pressure, temperature, and vibration conditions to ensure long-term safety and reliability.

Products can be supplied with full certification and traceability documentation to support compliance with regulated industry standards. Pressure testing, material certification, and third-party inspection can be provided upon request.

End Fittings and Accessories

A comprehensive range of end fittings is available, including flanged, threaded, and welded types. These fittings can be specified in a variety of materials to match process compatibility requirements.

Accessories such as outer protection covers, interlock casings, and fire sleeves can be incorporated to enhance safety and extend service life in harsh or exposed environments. Each assembly is designed to ensure a secure and leak-free connection suitable for the intended operating conditions.

Installation, Maintenance, and Support

Correct installation is essential to ensure long-term hose performance. Flexmetallic provides detailed installation guidance covering bend radius, alignment, and anchoring requirements. Following best practices prevents over-extension and vibration fatigue, significantly improving service life.

Maintenance recommendations include regular inspection for mechanical wear, signs of over-bending, and braid damage. Our technical support team is available to provide assistance with specification, installation planning, and troubleshooting.

Selection Guide

Selecting the correct hose or assembly depends on several key operating parameters including pressure, temperature, medium compatibility, movement, and installation environment. Our technical engineers can provide guidance to ensure the most appropriate product is selected based on the system’s operational and safety requirements.

FAQs

Related Product Links and Resources

Technical datasheets, certification information, and case studies are available for download on each product page. These documents provide detailed specifications, performance data, and installation guidance to support design and procurement decisions.

Other useful links:

- High pressure flexible metal hose assemblies

- Flexible metal hoses for steam and condensate systems

- Flexible Metal Hoses for Chemical and Petrochemical Processing

- Flexible Metal Hoses for Cryogenic and Low-Temperature Applications

- Flexible Metal Hoses for Fire Suppression Systems

- Flexible Metal Hoses in HVAC and Building Services

Expert Advice

For complex systems or specialist requirements, our technical engineering team is available to assist with product selection and specification. Contact Flexmetallic through our enquiry form for expert advice, custom assembly design, or a detailed quotation.