Blog: Industry

What to Look for in a Cryogenic Hose: Materials, Testing, and Application-Specific Features

17th July 2025

Cryogenic hoses are essential for safely transferring ultra-low temperature fluids and gases in industries such as healthcare, food processing, energy, and aerospace. Their design, materials, and construction must address the unique challenges of cryogenic environments, including extreme cold, pressure fluctuations, and chemical compatibility. This comprehensive guide details the features, standards, and innovations that make a hose suitable for cryogenic applications, providing actionable advice and practical examples for engineers, facility managers, and procurement specialists.

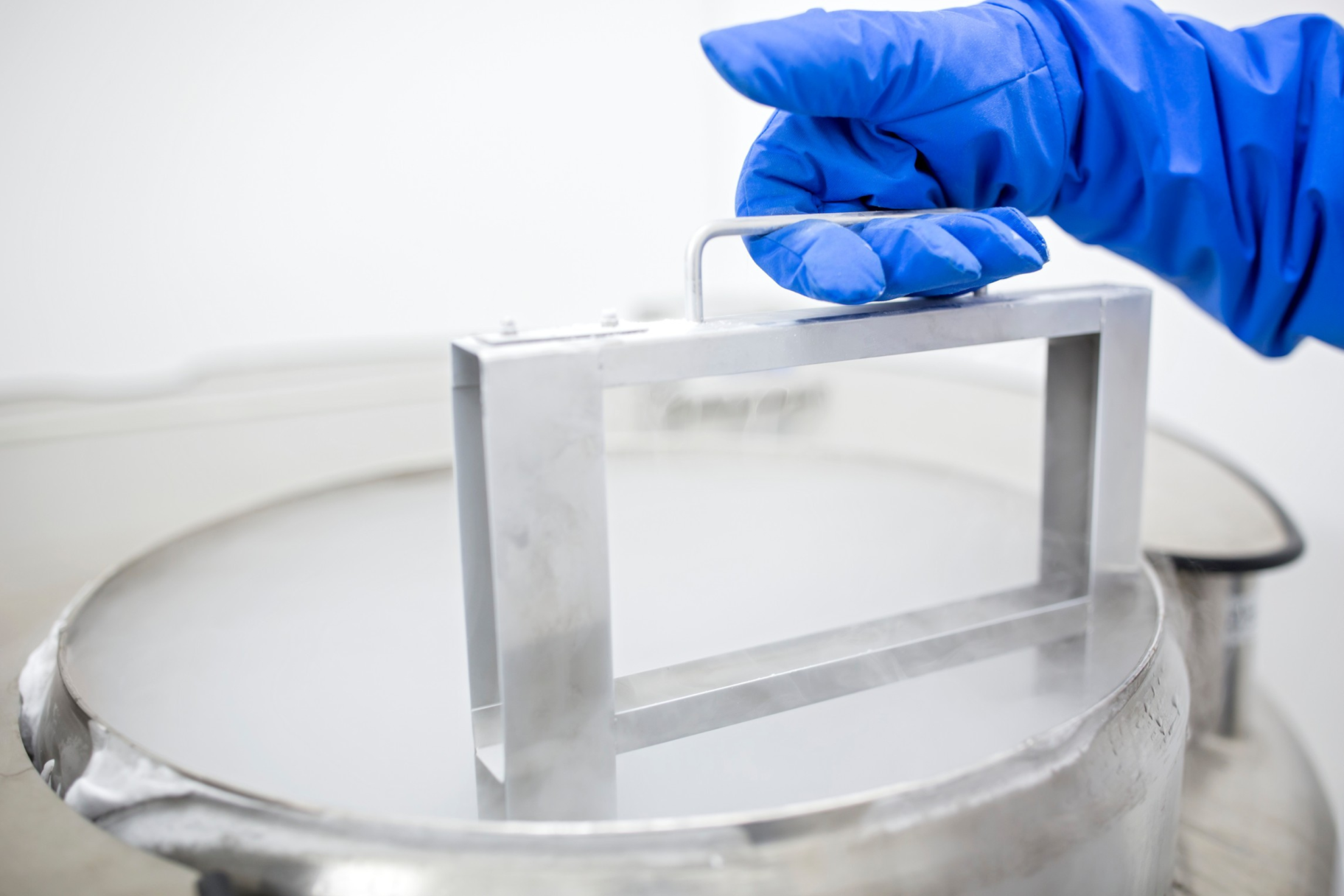

Understanding Cryogenic Applications and Their Demands

Cryogenic applications involve the handling and transfer of substances at extremely low temperatures, often below -150°C. Common uses include medical cryopreservation, liquefied natural gas (LNG) transfer, food freezing, superconducting electronics, and rocket fuel delivery. Such environments expose hoses to rapid temperature changes, potential material contraction, and embrittlement, requiring robust engineering and expert selection. For more on cryogenic solutions, see cryogenic hoses.

Selecting the Right Materials for Cryogenic Hoses

The choice of material is crucial for cryogenic hose performance. Stainless steel alloys such as 304, 316, and 321 are preferred for their flexibility, strength, and corrosion resistance at low temperatures. Nickel alloys may be used for enhanced durability and chemical compatibility. These materials prevent embrittlement and maintain hose integrity during rapid temperature fluctuations. For custom material options, visit bespoke metal hose assemblies.

Multi-Layered Construction and Thermal Insulation

Cryogenic hoses are often constructed with multiple layers, combining a metallic inner tube with insulating materials and protective outer coatings. This design minimises heat transfer, preventing premature warming or evaporation of cryogenic fluids. Spring guards and outer procoil wires reinforce bend points and protect against mechanical wear, extending the hose’s service life. For more details on construction, see cryogenic hoses.

Size Range, Pressure Ratings, and Flow Capacity

Cryogenic hoses are available in diameters ranging from 6mm to 300mm, with pressure ratings up to 300 bar. Correct sizing and pressure selection ensure safe, efficient transfer of cryogenic liquids and gases. Oversized or undersized hoses can lead to flow restrictions, pressure drops, or safety hazards. For technical guidance, see cryogenic hoses.

Flexibility and Resistance to Vacuum Collapse

Flexibility is essential for routing hoses through complex systems and tight spaces. High-performance cryogenic hoses retain flexibility at temperatures as low as -200°C, supporting easy installation and movement. Vacuum resistance prevents hose collapse during operation, ensuring consistent flow and safety in processes such as LNG transfer or medical gas supply. For flexible solutions, see engineering industry hoses.

Oxygen Cleaning and Helium Leak Testing

Cryogenic hoses must be free of contaminants that could react with oxygen-rich fluids. Oxygen cleaning removes hydrocarbons and particulates, while helium leak testing verifies assembly integrity. These quality assurance steps are vital for safety in healthcare, aerospace, and chemical processing. For certification details, see metal hose assembly certifications.

Protective Features: Spring Guards and Outer Procoil Wires

To protect against mechanical damage and abrasion, cryogenic hoses often include spring guards at bend points and outer procoil wires along their length. These features are especially important in industrial settings where hoses may be moved, flexed, or exposed to rough handling. Custom protective options are available for demanding environments. For bespoke solutions, visit bespoke metal hose assemblies.

Chemical Compatibility and Fluid Versatility

Cryogenic hoses must be compatible with a range of ultra-cold fluids, including liquid nitrogen, helium, argon, and hydrogen. Their construction resists chemical attack and maintains flexibility even when exposed to aggressive substances, making them suitable for diverse applications from medical labs to energy terminals. For compatibility information, see cryogenic hoses.

Applications Across Key Industries

Cryogenic hoses are used in healthcare for biological sample storage, in food processing for rapid freezing, in electronics for superconducting systems, and in energy for LNG and hydrogen transfer. Each application requires specific hose features, such as enhanced insulation, chemical resistance, or custom fittings. For sector-specific solutions, visit cryogenic hoses.

Customisation and Bespoke Engineering for Cryogenics

Every cryogenic system has unique requirements. Flex metallic offers bespoke hose assemblies with custom lengths, diameters, end fittings, and materials to ensure optimal performance and compliance. Customisation supports integration with specialised equipment and enhances system reliability. For tailored options, see bespoke metal hose assemblies.

Quality Assurance, Testing, and Certification

Cryogenic hoses undergo rigorous testing, including pressure cycling, thermal shock, and helium leak tests, to ensure compliance with standards such as ASME and ISO. Documentation and certification provide assurance of safe, reliable operation in critical environments. For more on testing and certification, see metal hose assembly certifications.

Maintenance, Handling, and Lifecycle Management

Proper maintenance and handling are crucial for preserving hose integrity. Regular inspections for wear, corrosion, and damage, combined with correct storage practices, extend service life and reduce risk. Training personnel on installation and maintenance best practices is essential for safety and compliance. For maintenance guidance, visit engineering industry hoses.

Innovations in Cryogenic Hose Technology

Recent advancements include improved alloy compositions for enhanced low-temperature performance, advanced insulation materials to reduce thermal losses, and the integration of sensors for real-time monitoring. These innovations increase safety, efficiency, and operational visibility in cryogenic systems. For the latest developments, see cryogenic hoses.

Environmental and Safety Considerations

Cryogenic hoses help prevent hazardous leaks and minimise fluid loss, supporting environmental safety and regulatory compliance. Their robust design reduces the risk of accidents when handling ultra-cold substances. Compliance with environmental and safety standards is integral to their design and use. For more on safety, see engineering industry hoses.

Future Trends in Cryogenic Hose Development

As cryogenic technology evolves, hoses are being developed with smarter monitoring, improved insulation, and greater adaptability for automated systems. These trends will further enhance safety, efficiency, and flexibility in industries relying on cryogenics. For ongoing advancements, visit cryogenic hoses.

How to Select the Right Cryogenic Hose

Selecting the ideal cryogenic hose involves evaluating temperature range, pressure requirements, chemical compatibility, flexibility, and installation environment. Consulting with cryogenic hose specialists and referring to certification documentation ensures optimal selection for your application. For expert advice, see cryogenic hoses.

Frequently Asked Questions: Cryogenic Hoses

What materials are best for cryogenic hoses?

Stainless steel alloys like 304, 316, and 321, or other nickel alloys, provide the best combination of strength, flexibility, and corrosion resistance.

How do cryogenic hoses prevent embrittlement?

They use specialised alloys and multi-layered construction with insulation to maintain flexibility and prevent brittleness at ultra-low temperatures.

Are cryogenic hoses compatible with all ultra-cold fluids?

High-quality cryogenic hoses are designed to handle a wide range of fluids including liquid nitrogen, helium, argon, and hydrogen safely.

Can cryogenic hoses be customised?

Yes, bespoke assemblies tailored to specific diameters, lengths, materials, and fittings are available to meet unique application requirements.