Flexible Metal Hoses for Chemical and Petrochemical Processing

Designed to withstand pressure, temperature, and corrosion challenges

Flexible metal hoses in chemical and petrochemical processing must combine mechanical reliability with proven resistance to corrosive, hazardous media. In environments where high pressures, temperature extremes, and aggressive chemicals converge, hose assemblies need to maintain integrity, protect people and plant, and comply with stringent industry standards.

Flexmetallic designs and manufactures flexible metal hoses and assemblies that address these demands, using high‑grade stainless steels, specialist alloys, and certified welding to create robust, leak‑tight connections for demanding process duties. From chemical transfer lines and loading arms to pump connections and steam services, these hoses support safe operation in plants where unplanned downtime or loss of containment is not an option.

Primary roles in process plants

Flexible metal hoses play several critical roles in chemical and petrochemical facilities, often where rigid pipework cannot adequately accommodate movement, vibration, or thermal expansion.

- Provide flexible connections for pumps, compressors, manifolds, and tank farm pipework, reducing loads on nozzles and equipment.

- Absorb vibration and cyclical movement in high‑pressure and high‑temperature systems, helping protect adjacent pipework and instrumentation.

- Compensate for misalignment and thermal expansion in lines carrying hot oils, steam, condensate, and chemical media, maintaining system integrity over time.

When specifying connections for new or retrofit projects, engineers can review the full range of flexible metal hose assemblies to match each duty to an appropriate configuration.

Materials and specialist alloys

Material selection is central to ensuring flexible metal hoses withstand corrosive and hazardous media. Flexmetallic’s hoses are typically manufactured from stainless steel grades such as 304, 316, and 321, chosen for their balance of corrosion resistance, strength, and flexibility.

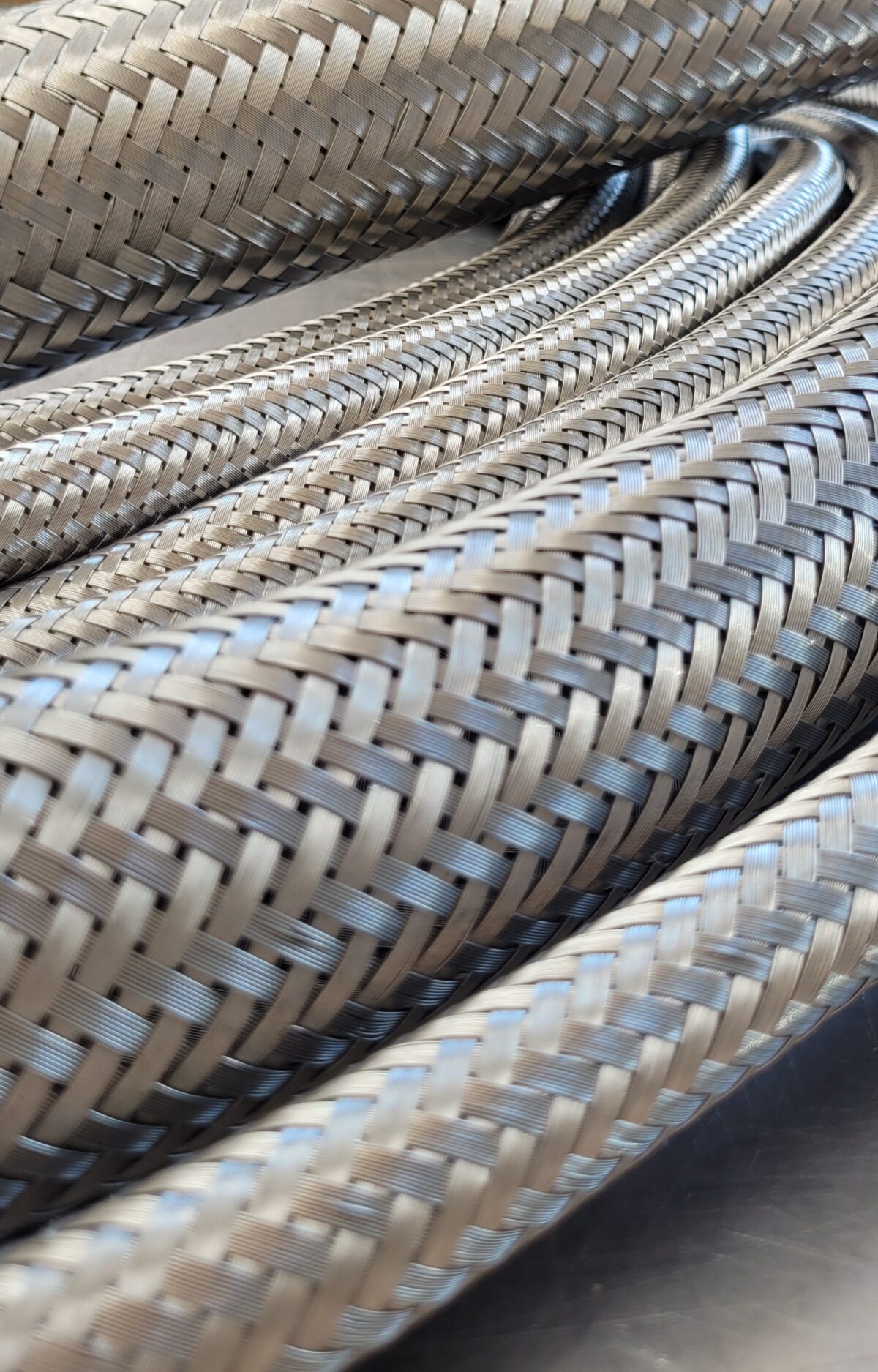

For more aggressive services, alternative materials and multi‑layer constructions can be specified to enhance chemical resistance, temperature capability, or fatigue life, with options guided by chemical resistance tools and alloy cross‑reference data. By combining a corrugated flexible metal hose core with one or more layers of stainless‑steel braid, assemblies are engineered to manage both internal pressures and external mechanical stress.

Secure, TIG welded hose assemblies

Leak‑tight performance in chemical service depends on both hose construction and end‑connection quality. Flexmetallic uses TIG welding to attach standard and bespoke fittings, providing strong, corrosion‑resistant joints suited to aggressive and high‑pressure applications.

The in‑house welding team is qualified to BS EN 9606‑1 and ASME IX, supporting consistent, certifiable weld quality for a wide range of process conditions and customer specifications. Each flexible metal hose assembly can be configured with flanged, threaded, or fully welded ends, allowing integration into existing systems while maintaining robust pressure boundaries.

Pressure, temperature and dynamic performance

In chemical and petrochemical processing, hoses often see high internal pressures, thermal cycling, and repeated movement. Flexmetallic’s high‑pressure flexible metal hose assemblies use tightly woven stainless‑steel braids over corrugated hose to provide exceptional pressure containment and resistance to mechanical fatigue.

These assemblies are carefully sized and rated for defined pressure, temperature, and vibration envelopes, supporting safe operation in applications such as chemical transfer, gas manifolds, pressurised steam, and heated lines. The corrugated construction maintains flexibility, allowing each flexible metal hose to absorb pulsation and movement without compromising the integrity of the pressure envelope.

Safety, compliance and certification

For hazardous and corrosive media, documented compliance is as important as mechanical design. All Flexmetallic metal hose assemblies are manufactured in strict accordance with ISO 10380, the international standard defining requirements for corrugated metal hose and hose assemblies.

The company operates an ISO 9001‑approved quality management system, and can provide 3.1b material certification, test certificates, and Certificates of Conformity to demonstrate traceability and conformance for regulated sectors. Traceability can be enhanced further by permanently etching each flexible metal hose assembly so that installed components can be matched directly to their certification records.

Managing corrosive and hazardous media transfer

Chemical and petrochemical processes often involve acids, solvents, hydrocarbons, and other hazardous substances that demand controlled, secure transfer. Flexmetallic’s fully stainless‑steel constructions provide broad chemical compatibility, fire resistance, and high‑temperature performance, making them suitable for many corrosive and flammable services.

By selecting appropriate grades, wall thicknesses, braid configurations, and protective coverings, assemblies can be tailored to manage permeation, erosion, and external environmental conditions, reducing the risk of leaks or premature failure. Where a braided flexible metal hose is required for additional mechanical protection, stainless‑steel overbraid can be specified to enhance pressure capacity and abrasion resistance.

Bespoke engineered solutions

Chemical and petrochemical facilities frequently require non‑standard routing, tight envelopes, or specific connection details. Flexmetallic provides custom engineered assemblies, combining in‑house design, manufacturing, and welding to create TIG‑welded stainless‑steel hoses tailored to each duty.

Engineers can specify parameters including live length, movement range, pressure rating, temperature range, and end connections, with design support available to optimise hose geometry and braid selection. This approach helps align each flexible metal hose assembly with process conditions, minimising stress concentrations and extending service life in demanding environments.

Integration with steam and utility systems

In many plants, flexible metal hoses used for chemical transfer also interface with steam, condensate, and heating systems for jacketed lines, tracing, or cleaning duties. Flexmetallic stainless‑steel hoses are engineered to withstand steam temperatures and pressures, enabling safe use in steam and condensate systems as well as process utilities.

Their ability to accommodate thermal expansion and contraction helps protect connected equipment, while braided metal hose constructions add strength and abrasion resistance where hoses are exposed or routed through congested pipe racks. Consolidating process and utility hose specifications with a single platform of flexible metal hose assemblies can simplify maintenance and inspection regimes across the plant.

Quality assurance and testing

To support safe use in hazardous areas, Flexmetallic tests 100% of hoses in accordance with ISO 10380 as standard, with options for high‑pressure and helium leak testing where required. This approach helps verify integrity before installation and supports compliance with site and regulatory requirements for hazardous media systems.

Combined with ISO 9001 quality management, ISO 10380 design and test compliance, and welded joint qualifications to BS EN 9606‑1 and ASME IX, this testing regime provides confidence that each flexible metal hose assembly is suited to the rigours of chemical and petrochemical processing.

FAQs

Conclusion and next steps

For chemical and petrochemical processing facilities handling corrosive, hazardous media, flexible metal hoses must deliver proven mechanical performance, corrosion resistance, and documented compliance. Flexmetallic’s TIG‑welded stainless‑steel and alloy hose assemblies, backed by ISO 9001, ISO 10380, and recognised welding qualifications, offer a robust platform for safe fluid and gas transfer in these environments.

To explore available flexible metal hose assemblies, flexible metal hose options, and braided flexible metal hose configurations in more detail, use the flexible metal hoses and assemblies pillar page as the central reference point when developing specifications for chemical and petrochemical applications.