Flexible Metal Hoses for Fire Suppression Systems

Critical role in suppression networks

In fixed fire suppression systems, consistent and dependable water or agent delivery is essential to protect people, assets, and structures. Flexible metallic hose assemblies are used wherever systems must accommodate building movement, vibration, or tight routing while maintaining secure connections between valves, pumps, pipework, and discharge devices.

Flexmetallic’s grooved flexible metallic hoses are used extensively in sprinkler and suppression networks across commercial buildings, industrial plants, data centres, and high‑risk facilities. Their adaptability and corrosion‑resistant construction support long‑term reliability in environments where system failure is not an option.

Pressure and temperature resilience

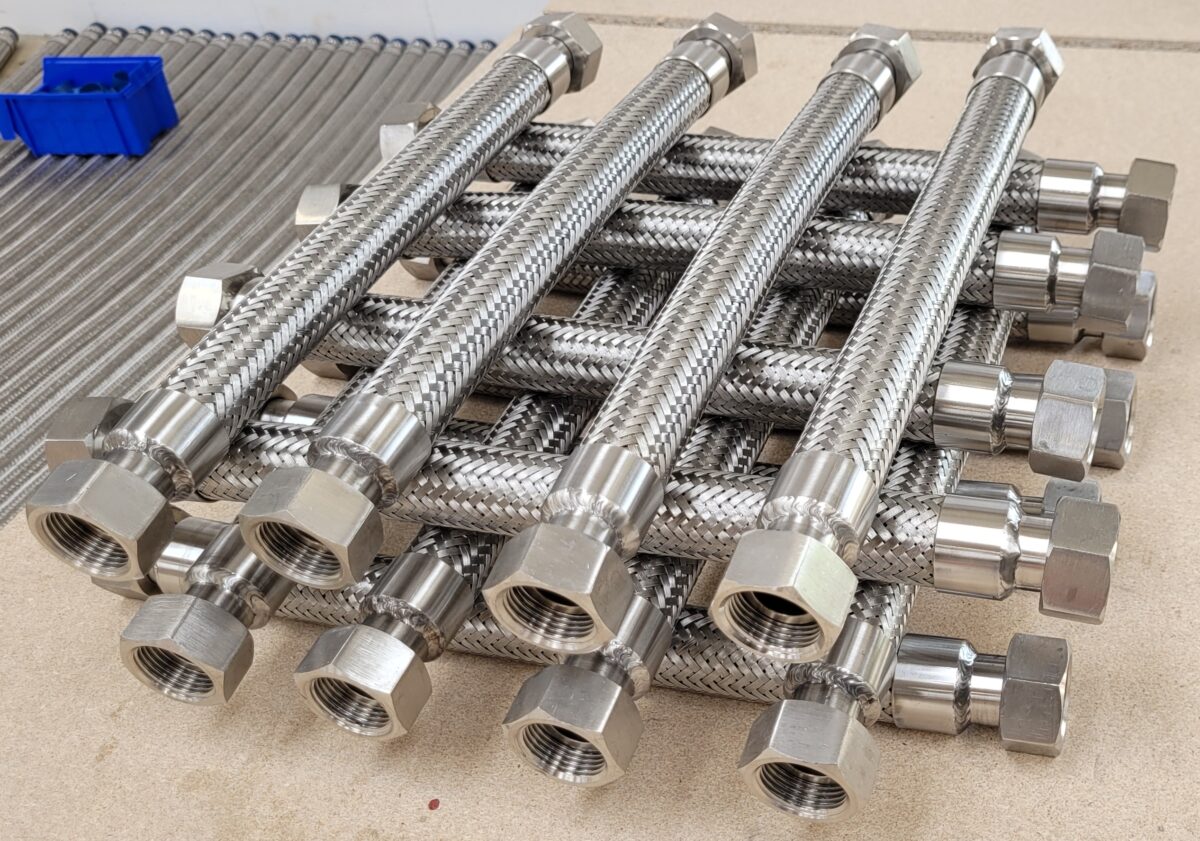

Fire suppression systems operate at pressures that demand robust, high‑integrity hose constructions. Flexmetallic uses corrugated stainless‑steel cores with external stainless‑steel braid to create flexible conduits capable of containing elevated system pressures while tolerating vibration and dynamic movement.

These hoses also offer excellent temperature resistance, important where water supplies may see seasonal temperature swings, where steam is present, or where fire exposure must not cause hose failure. A correctly specified flexible metal hose assembly provides high burst margins, fatigue resistance, and fire‑resistant materials, all contributing to dependable performance under fire conditions.

Durable construction and materials

Flexmetallic fire suppression hoses are typically manufactured from stainless‑steel grades such as 304, 316, and 321, selected for corrosion resistance, strength, and fatigue performance in building and industrial environments. The corrugated hose provides flexibility, while stainless‑steel overbraid adds mechanical protection and pressure capability.

Where higher pressures or additional mechanical protection are needed, a braided flexible metal hose can be specified, including single and double‑braid variants for enhanced containment. For interfaces with other materials or specific media conditions, a suitable metal braided water hose can combine a compatible inner with stainless‑steel overbraid for added robustness.

Integration with grooved and specialised systems

Grooved flexible metallic hoses are widely used in fire protection systems because they integrate easily with grooved couplings, valves, and manifolds. This simplifies installation, allows rapid changes during commissioning or retrofit work, and supports prefabrication and modular build approaches.

At the same time, the broader flexible metal hose range can be configured with different end fittings – grooved, flanged, or threaded – to interface with pumps, risers, and distribution pipework. Flexmetallic can also supply bespoke fire suppression assemblies tailored in length, diameter, and fitting type for specific projects or retrofit constraints.

Vibration, movement and misalignment control

Fire pumps, jockey pumps, and other suppression equipment generate vibration and are often located in plantrooms subject to structural movement. Flexible metallic hoses absorb this vibration and accommodate misalignment between equipment and fixed pipework, helping to protect seals, flanges, and welded joints from fatigue.

By using a short length of metallic hose at critical interfaces, designers can reduce nozzle loads and enhance service life for pumps, valves, and ancillary equipment. In seismic or high‑movement environments, these characteristics also support resilience against building movement and thermal expansion.

Reliability, maintenance and lifecycle value

Suppression systems are often dormant for long periods and then expected to perform instantly under emergency conditions, placing emphasis on long‑term integrity rather than everyday duty. Stainless‑steel metallic hoses offer excellent resistance to corrosion, UV, temperature variations, and mechanical damage, helping to maintain system readiness with minimal degradation over time.

Extended service life and reduced maintenance intervention contribute to lower whole‑life costs, particularly in large commercial and industrial estates where many suppression hose assemblies are installed. Using a consistent family of hose assemblies across a site also simplifies inspection, spare‑parts stocking, and documentation.

Selection and best practice installation

Selecting hoses for fire suppression duties involves confirming system pressure, test pressure, temperature range, medium (usually water or water‑based agents), movement, and environmental conditions. Flexmetallic’s technical tools and datasheets provide guidance on sizes, pressure ratings, bend radii, and braid configurations to help specifiers choose the right metal braided hose or assembly for each location.

Installation should respect minimum bend radius, avoid torsion, ensure correct support, and protect hoses from mechanical damage or sharp edges. In demanding positions, specifying braided constructions with additional guards, pro‑coil, or external protection can further enhance robustness and service life.

FAQs

Next steps

For fire suppression systems that demand durable, high‑integrity hose connections capable of withstanding pressure, temperature, and mechanical stresses, flexible metallic hose assemblies provide a trusted solution. To review available configurations and technical options, and to specify flexible metal hose assemblies or related metallic hose configurations for your fire suppression project, use the flexible metal hoses and assemblies pillar page as your primary reference point for detailed product and engineering information.