Flexible Metal Hoses in HVAC and Building Services

Role of flexible hoses in buildings

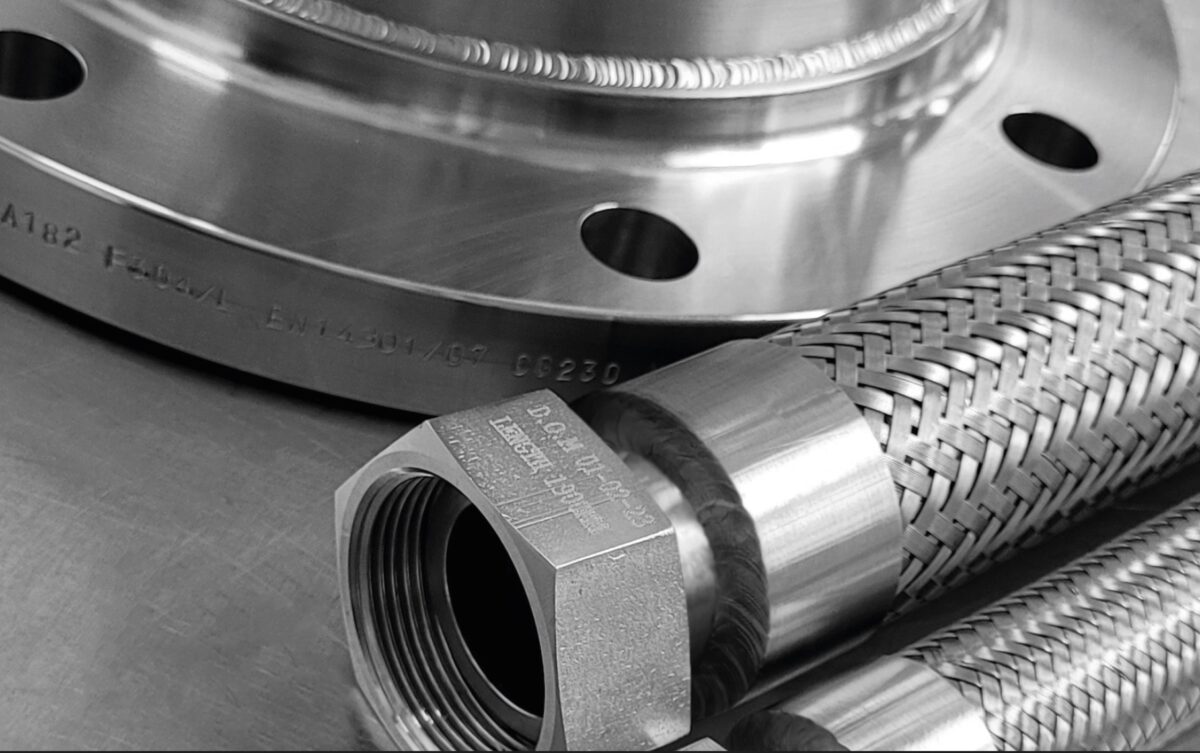

In the engineering, building, and HVAC sectors, metallic hose assemblies are used wherever systems must cope with movement, vibration, or constrained routing. They connect pumps, chillers, boilers, air‑handling units, fan‑coil units, and riser pipework, supporting reliable operation over thousands of cycles.

Fully stainless‑steel constructions from Flexmetallic are designed to provide long service life in these environments, resisting corrosion and fatigue while maintaining leak‑tight performance. For projects that need proven, engineered solutions, designers can select a suitable flexible metal hose assembly to match pressure, temperature, and movement requirements.

Vibration absorption and equipment protection

Rotating HVAC equipment generates vibration that can rapidly damage rigid pipework or connected plant if left uncontrolled. Corrugated stainless‑steel hoses introduce a flexible section that absorbs vibration and decouples pumps, fans, and compressors from building pipework and structure.

By installing a short length of flexible metal hose at equipment nozzles, designers reduce nozzle loads, limit fatigue cracking at welds, and help prevent nuisance noise and vibration in occupied spaces. In high‑vibration locations, the additional pressure and mechanical performance of a braided flexible metal hose offers further protection.

Managing thermal expansion and building movement

Heating, chilled‑water, and condenser‑water systems expand and contract as operating temperatures change, while buildings themselves move due to settlement, wind, and live loads. Metal hoses, with their inherent flexibility and resilience, provide a practical method of absorbing this movement without overstressing pipework, anchors, or equipment.

Strategically placed lengths of flexible metal hose can accommodate axial, lateral, and angular movements that would otherwise require large expansion loops. For larger movements, metallic bellows and expansion joints can be combined with braided metal hose sections to create compact, engineered solutions for hot‑ and cold‑water distribution.

Routing through tight and congested spaces

Modern buildings often have dense services corridors and limited ceiling and riser space, making rigid pipework difficult to install. Corrugated stainless‑steel hoses can be pre‑fabricated to length with end fittings, then flexed into position around obstacles and through tight openings without excessive joints or fittings.

Using a flexible metal braided hose or braided metal hose allows installers to follow the desired route while maintaining pressure capability and mechanical integrity. This simplifies installation in plantrooms and retrofits, and can reduce time on site compared with complex rigid pipe spools.

Materials, media and temperature ranges

Flexmetallic hoses for HVAC and building services are typically manufactured from stainless‑steel grades such as 304, 316, and 321, using a corrugated core for flexibility and stainless‑steel braid for pressure containment. These materials are suited to common HVAC media such as hot and chilled water, glycol mixtures, and low‑pressure steam, as well as a wide range of cleaning and dosing chemicals.

Where a metallic sheath is needed around non‑metallic liners, a metal braided rubber hose or metal braided water hose can combine the flexibility of rubber with the protection and pressure capability of stainless‑steel overbraid. The broader flexible metal hose assembly range covers operating temperatures from roughly minus 200 °C up to around plus 600 °C, offering ample capability for typical HVAC duties.

Efficiency, reliability and lifecycle advantages

By managing vibration, misalignment, and movement, flexible metal hoses help HVAC systems operate closer to design conditions, reducing unplanned restrictions and stress points. Their smooth corrugated bores and correctly controlled bend radii support stable flow, helping to minimise pressure losses added by poorly aligned or forced pipe runs.

Stainless‑steel construction resists UV, temperature, and mechanical damage better than many polymer hoses, contributing to longer service life in plantrooms, rooftops, and exposed locations. Across a building’s life, using appropriate flexible metal hose assemblies can reduce maintenance intervention, lower the risk of leaks at highly stressed joints, and support consistent system performance.

Practical selection and installation guidance

Selecting the right hose involves defining pressure, temperature, movement, vibration level, and media compatibility, then matching these to the appropriate construction and braid. Flexmetallic provides data on velocity limits, temperature correction factors, and minimum live lengths to help designers select and size each flexible metal hose correctly.

Installation good practice includes supporting hoses adequately, respecting minimum bend radii, avoiding torsion, and protecting against abrasion or impact. Where loads or vibration are higher, specifying a braided flexible metal hose or flexible metal braided hose with guards, pro‑coil, or over‑bend limiters can further enhance reliability.

FAQs

Next steps

For HVAC and building‑services projects that demand durable, vibration‑tolerant connections in tight or mobile pipework runs, flexible metal hoses offer a proven, stainless‑steel solution. To specify suitable flexible metal hose assemblies, flexible metal hose, or braided flexible metal hose for your building, use the flexible metal hoses and assemblies pillar page as your starting point, then follow the links to the detailed product catalogues and datasheets for final sizing and selection.