High-Pressure Flexible Metal Hose Assemblies

Reliable Solutions for Demanding Industrial Applications

In high-pressure industrial systems, reliability and safety are paramount. Flexmetallic’s high-pressure flexible metal hose assemblies are engineered to perform under the most demanding conditions, ensuring safe, leak-free transfer of fluids and gases. Built from premium stainless steel and available in a variety of pressure-rated configurations, these hoses are designed to maintain flexibility without compromising strength. For a complete overview of our range, visit the metal hose assemblies hub page.

Engineered for Extreme Pressure Performance

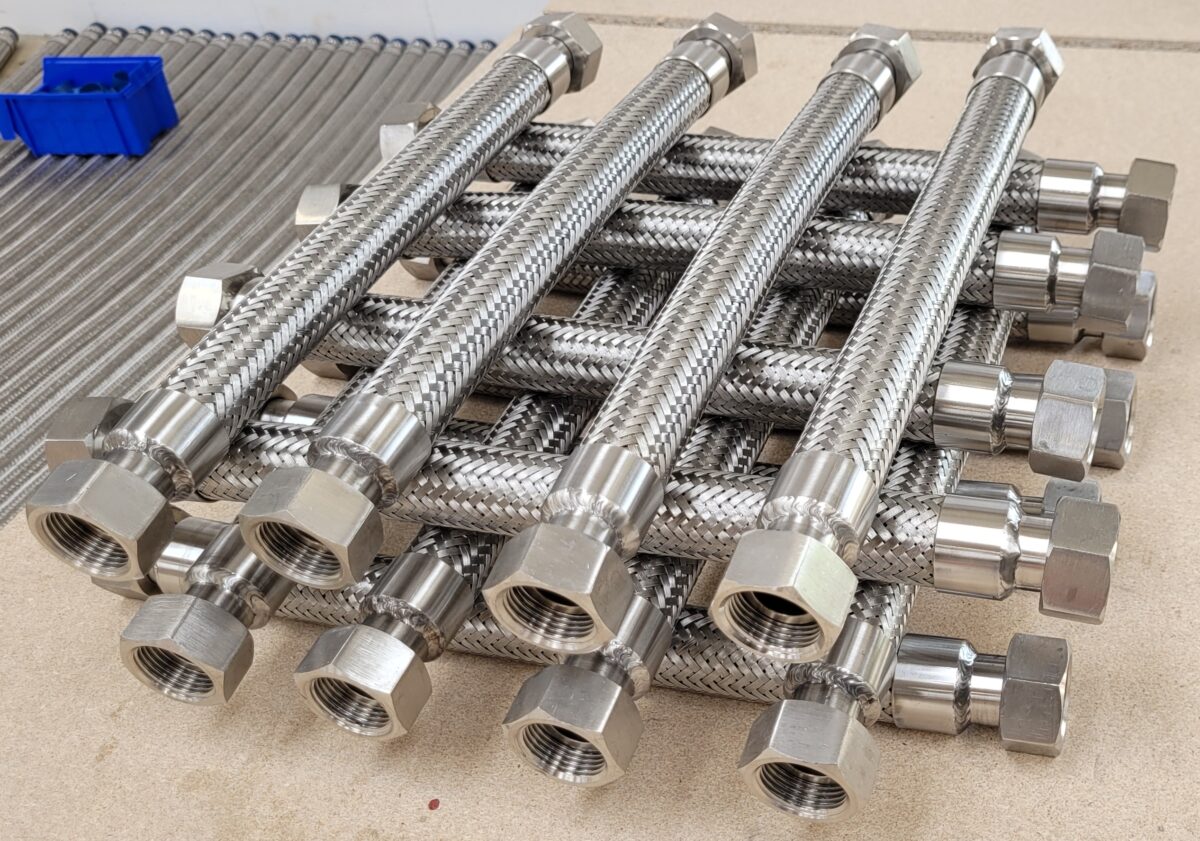

High-pressure applications demand hose assemblies that can tolerate substantial internal loads while maintaining durability and integrity. Flexmetallic’s corrugated metal hoses are reinforced with tightly woven stainless steel braids, providing exceptional pressure containment and protection against mechanical stress.

Each assembly is carefully designed to accommodate specific operating pressures, vibration levels, and movement patterns, ensuring long service life and consistent performance. Typical applications include hydraulic systems, chemical process transfer, gas manifolds, and pressurised steam systems where precision and reliability are critical.

Double Braiding for Strength and Stability

Double-braided designs enhance the capability of high-pressure hoses by adding a secondary sheath of stainless steel wires around the primary braid. This construction increases operating pressure capacity, minimises elongation under load, and prevents external abrasion.

The inner corrugations allow flexibility for movement and vibration absorption, while the outer double braiding provides reinforcement and resistance to mechanical damage. This synergy between flexibility and strength ensures a secure, stable connection in installations that experience pressure surges or dynamic movement.

In environments subject to pulsation or sustained high pressure, double-braided hoses deliver optimal reliability. Flexmetallic’s experts can advise on the ideal braid configuration and wall thickness to meet the specific safety factors of each system.

Material Selection and Corrosion Resistance

Flexmetallic’s high-pressure hoses are available in a variety of stainless steel grades to suit different fluid media and corrosive conditions. Common choices include 304, 316, and 321 stainless steel, which offer excellent resistance to oxidation and stress cracking. For specialist requirements, alternative alloys can be supplied to ensure full compatibility with the application environment.

Proper material selection extends service life, maintains mechanical strength, and reduces maintenance frequency, supporting optimum operational efficiency in critical industries such as petrochemicals, power generation, and offshore systems.

Safety and Regulatory Compliance

Safety lies at the core of every Flexmetallic hose assembly. Each unit is manufactured and pressure-tested in accordance with recognised international standards. This includes hydrostatic and pneumatic testing to verify performance under both operating and surge conditions.

All hoses undergo dimensional checks, visual inspections, and weld integrity testing. For pressure-critical projects, test certificates and material traceability documentation can be provided to meet client and regulatory requirements.

Key safety features include:

- High burst pressure margins and fatigue resistance

- Secure end connections with welded or mechanically attached fittings

- Stainless steel construction offering fire and corrosion resistance

- Design compliance with BS 6501, ISO 10380, and related quality standards

These features ensure that Flexmetallic hoses deliver dependable containment and performance, even under extreme conditions.

Designed for Versatility and Integration

High-pressure metal hose assemblies can be configured with a wide selection of fittings and terminations, allowing seamless integration into new or existing systems. Standard end fittings include flanges, threaded connections, and quick couplings, available in multiple pressure ratings.

Their flexibility makes them particularly well-suited for applications where rigid metal pipework cannot accommodate thermal movement, vibration, or misalignment. By absorbing stress and motion, these hoses help prevent fatigue and damage to adjoining components.

To explore integration options across industrial and energy systems, visit our flexible hose assemblies information page.

Testing, Quality Assurance, and Certification

Each Flexmetallic hose assembly is manufactured under tightly controlled conditions. During production, welds are performed using approved techniques and inspected for conformity. Following assembly, hoses undergo 100% pressure testing to validate their performance and leak integrity.

Testing processes can include:

- Pneumatic leak test as per ISO10380

- Hydrostatic pressure testing up to and beyond working limits

- Helium and nitrogen leak testing for gas service

- Life cycle and vibration testing for fatigue resistance

- Visual and dimensional checks for consistency and finish quality

Quality assurance is maintained through ISO-certified manufacturing systems, ensuring that every hose leaving the production line meets Flexmetallic’s exacting standards for safety and durability.

Benefits of High-Pressure Flexible Assemblies

Flexmetallic’s high-pressure hoses bring measurable value in performance, safety, and efficiency:

- Safe operation under extreme pressure conditions

- Excellent flexibility and vibration control

- Reduced risk of thermal expansion damage

- Long lifespan and low maintenance requirements

- Stable and leak-free operation under cyclical loads

These advantages make them a preferred choice across refineries, chemical plants, compressed gas systems, and high-temperature fluid networks.

Supporting Industry and Energy Applications

Flexmetallic’s engineering expertise ensures that each high-pressure flexible metal hose assembly is not only built to specification but also optimised for long-term performance in challenging industrial settings. Our dedicated support and technical team work with clients to match hose construction to operational demand, enhancing safety and system reliability.

To see how our products support power generation, energy transmission, and process automation projects, visit our metal hose and assemblies hub page.

About Flexmetallic

Flexmetallic is a specialist manufacturer of metal hose assemblies, expansion joints, and engineered flexible connectors for demanding industrial environments. With advanced manufacturing capabilities and a strong commitment to quality, we ensure safe, efficient performance across sectors including energy, chemical processing, and infrastructure. Our focus on design precision and technical support guarantees that every assembly performs reliably under pressure.